For most forklift marina owners Aero-Docks robotic storage systems are a paradigm shift in thinking about boat dry stack storage. System III allows the greatest design flexibility to match your site requirements and marina’s long term goals. Building distance from water is flexible and this equipment offers the best ability to accommodate greatest variety of boat sizes and types. See the following presentation titled SYSTEM III TUTORIAL with explanations of all aspects of this incredible designed machine. Also below is a section dedicated to just the unique patented traveling transport elevator using our traveling tugs a breakthrough engineering marvel to “lift and shift” all boats. Flexibility for the owner is the key to this systems design. All unique functions are detailed with images and our HD Video on Video page. System III by Aero-Docks is the future of dry stack marinas.

AERO-DOCKS PATENTED SYSTEM III:

OUR MOST VERSATILE BOAT STORAGE EQUIPMENT

Marquis 72 ft (24.5m) fly bridge - visit the website

Aero-Docks creates an entire NEW MARKET for marina owners from high net worth large yacht owners. Forklifts are limited to boats 46 ft (15.5m) of speed boat design. Aero-Docks can store 46 to 75ft+ (23m) and 175,000 lbs(80,000kg), this category includes Cruisers and Yachts with a fly bridge. Also owners of these expensive vessels have no opportunity to store their boat/yacht inside a weather proof building anywhere in world. Your marina will have no market competition thus you can charge a more profitable rate per foot above 38 ft. Applying this unique capability can only be done with Aero-Docks. This market of boat sizes, until now, must sit in the water. Your Aero-Docks Marina’s available large yacht storage space is filled very quickly even in area’s with many dry stack marina’s.

Reliability, is built into all movement parts of System III so if any 1 or even 2 motors fail-- the system will operate at 50% capacity…thus allowing the marina owner to continue to launch and retrieve boats. (See our Warranty page for details about our 2 year warranty and 20 year extended full parts/labor customer service agreement all serviced by Rockwell Automation.) Typical manufacturing and construction schedule is 7 to 14 months depending on scope of project and system.

DENSITY KEY TO HIGH PROFITS

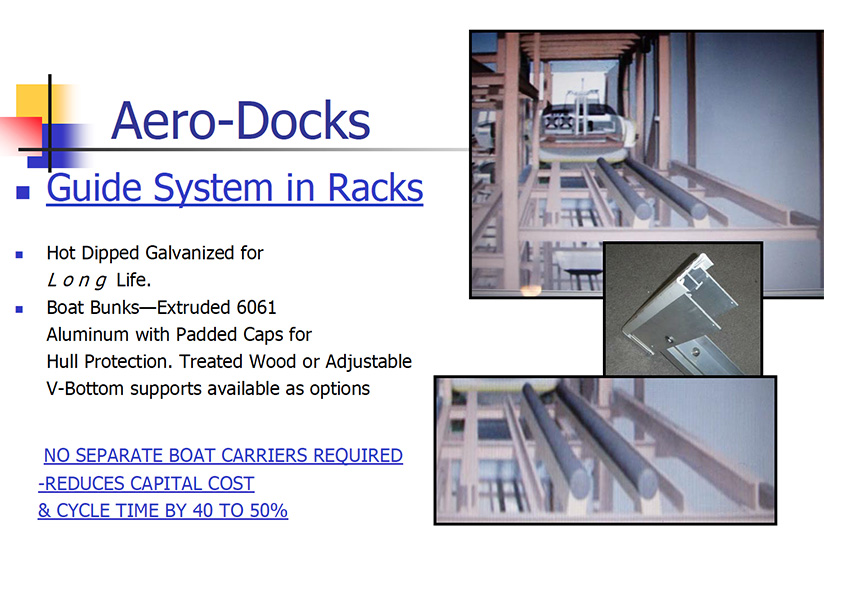

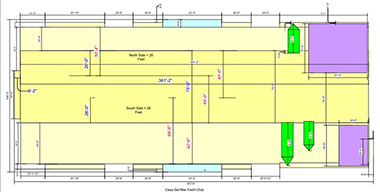

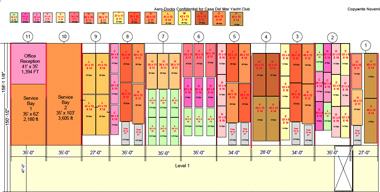

Aero-Docks System III stores 40-55% more boats depending on layout in EXACT same size building footprint and height of forklift dry stack. System III’s unique ability to work in a building maximum of 200 feet (61m) in height allows 250% more boats on same amount of land when going above the 61 ft (19m) maximum for a forklift building. See Casa Del Mar project detailed design layout comparison of forklift dry stack system to our System III designed layout later this page. We put 46% more boats in exact same building and increased linear footage available and PROFITABLE INCOME by 86%! Our System III does NOT use individual boat carriers which is a significant cost and cycle time savings. Systems attempting to use carriers have their cycle times greatly increased due to once boat is launched the boats carrier must be returned into building. Aero-Docks system is ready to retrieve or launch another vessel immediately offering 20-30 boats per hour launch/retrieval.

SeaRay 54 - visit the website

System III is the perfect solution for a marina’s high cost per acre land allowing far greater income up to 250% MORE by going vertical that other systems cannot match. This is why AERO-DOCKS delivers VERTICAL SUPREMACY.

FOUR REASONS WHY OUR SYSTEM III STORES MORE BOATS

- Aisle is 30% narrower than forklift as our aisle only needs to be 2 ft longer than longest boat giving more space for boats to be stored.

- Longest boats can be stored top levels where forklift higher it goes less weight it can lift. This creates a triangle of space in front of boats on 3rd and 4th level providing no income from paid for building space. With forklift this restriction of shorter boats top 2 levels greatly reduces mix of boats you can store.

- Aero-Docks building height can be 200ft ( 60m) vs. maximum of 62ft(19m) for forklift building. Additional 220% of boat storage space on SAME land. Converting AIR SPACE above building that a forklift can never use.

- In forklift building if max row length is 45 ft most always boats less than 45ft are stored leaving often 25%-35% lost income from space that is there but empty. Aero-Docks ability to put 2-4 boats one row and computer density software matching mix of boat lengths so up to 90%+ linear footage/meter all rows all levels are income producing.

Click here to see the detailed Casa Del Mar layout diagrams showing how our System III adds 46% more boats and increased usable income linear feet(meters) from 8,847 to 12,402 ft. in the exact same building.

SYSTEM III TUTORIAL:

Typical System Design, System Details, Installation and Project Construction Details

CASA DEL MAR MARINA PROJECT LAYOUT & DIAGRAMS

This project had an existing designed forklift marina when owners came to Aero-Docks. Although this project does NOT take advantage of System III’s important advantage of boats larger than a forklift can lift. The 46-75ft (23m)+ yachts grant a new untapped market to a marina using our System III also allowing greatly increased charge per foot/meter as there is no competition to push rates downward plus willingness of larger vessel owners to pay handsomely for indoor storage instead of always sitting in the water. With this forklift prior design/permitted layout the only control parameter was we had to use exact same length, width and height structure. Aero-Docks design shows our powerful key advantage of adding 46% more boats and increasing income from linear footage (meters) from 61% to 86% in same building! Casa Del Mar is a showcase designed marina having a spacious greeting/waiting lobby and two large service bays. Having been involved in the auto industry I learned that the best auto dealerships built an excellent service department. Knowing that during times of economic average to tough times people still had to service their car. Also profit margins are very high from parts and labor for dealer providing supporting cash flow when new sales drop. Casa Del Mar uses this philosophy first to greatly increase profit/gross income but also to generate strong marina member loyalty.

SORTING OPTIMIZATION SOFTWARE

You will also see the fantastic advantage our sorting optimization software unique in the boating world has. It optimizes each night where boats are stored allowing each new boat added to be placed with other boats in a row to use 90% or more of linear footage (meters). Marina owners know that over past few decades the size and type of boats (MIX) changes. A forklift marina due to only one boat per row ( one each side of space wasting wide aisle) is forced in most slots to place a shorter boat than length of slot losing that income. Also often a marina must turn away potential members due to no space for their size boat currently available even though linear footage is there. Aero-Docks System III has no such limitations, instead granting the marina owner ability to re-sort boats to create space needed for new boat owners especially into future when the MIX of boats changes.

The Aero-Docks marina will always be able use nearly all linear feet in building now and most important decades into the future no matter the mix of boats. Another equally important Aero-Dock advantage is this optimization software stores the usage of the boat owners and adjusts during night to move these boats close to launch entrance of building allowing 2-3 min. launch times. The optimization program can be manually initiated by marina owner if preferred. Truly automation and computer controls move Aero-Docks into the 21st century something forklift marinas can never leave the dark ages of significant disadvantages a forklift marina must live with. We do offer hope for forklift operations with a System III retrofit.

CLICK HERE TO SEE OUR DETAILED COMPARISON LIST FORKLIFT MARINA PROBLEMS vs. AERO-DOCKS AUTOMATED ADVANTAGES

PROJECT DESIGN – AERO-DOCKS SYSTEM OR COMPLETE MARINA

When designing a dry stack marina a few general rules apply. The width or beam between steel columns once built is fixed thus you can put a narrower boat in but not larger. The height can have adjustable crossbeams allowing this ability to change additionally your boat mix in future. This is why we at Aero-Docks stress the importance that in your area you study and know the market type and size of boats available to your marina. For existing dry stack marina owners you have this valuable information. Although the length of boats in a System III dry stack becomes much less important, knowing the beam of boats you are targeting and are available is critical to know so that you allocate enough stacks with wider width/beam. Guessing at this can create a degree of lost income. This area of boat mix is one that our firm will NOT recommend other than to consult with your provided expected boat mix to facilitate the most efficient layout design.

Our staff at Aero-Docks is truly dedicated to providing you all the help possible to design and build a world class highly profitable robotic high density boat storage facility and marina. As a general rule a dry stack marina should have 7 -15% wet slip dockage (staging docks) available to total boats stored. This assures boat owners a place to dock when returning or a boat ready in water to launch when owner arrives at marina. Our research from our Solamar Yacht Club trade show booth at boat shows, has shown overwhelmingly the chief complaint at dry stack marinas is wait time to go boating and worse forced to wait in water near marina because an open dock is not available. Happy marina members tell many people unhappy ones tell everyone causing long term capacity problems as image is hard to change once set. The percentage of dockage depends on expected peak volume launch and retrieval.

COMPLETE PROJECT MANAGEMENT

As your project takes shape you have the option to choose Aero-Docks as project Director to handle the complete project (depending on your location) or just our system design and installation. A true turnkey automated dry stack facility and marina complete including daily operations once completed can be part of our project proposal. You provide the land, marketing data boat mix, funding and your vision; we can do the rest.

Over the years we have worked with and aligned ourselves with some of the best contractors in the following areas:- Architects

- Building Construction and Design - Integrated uniquely to our System’s

- Coastal Engineers

- Seawall and Dock builders

- General Contractors

- Marina Management Services-Aero-Docks management division, Florida-Marine is ready to manage and staff your marina.

ROCKWELL AUTOMATION INTELLIGENT MOTOR CONTROL

Aero-Docks Systems use numerous motors and sensor controls all computer logic controlled to within .04 inch(1 mm) accuracy. View video made by Rockwell Automation our strategic partner.